Toilet water supply line come in three styles. Most of the time, you have a 3/8" fitting at the shut off valve and a 7/8" fitting at the toilet tank.

Toilet water supply line come in three styles. Most of the time, you have a 3/8" fitting at the shut off valve and a 7/8" fitting at the toilet tank.

Do you have a different Problem? See 'Plumbing Repair' or 'How to Fix a Toilet' for a complete listing of related topics.

Chrome Plated Brass

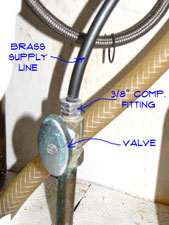

In the past you had to purchase a 3/8" brass tube that had a special flared end on it. This tubing was often chrome plated. The tubing had to be bent and cut to length. At the valve, a compression fitting is used.

The brass tubing has a couple of draw backs. First the tubing is stiff and needs to be bent into the proper shape to align properly. Kinking the tubing is a very real possibility. A kinked line should be thrown away and another supply line obtained. The other issue is cutting it to length. Obviously, cutting it too short renders it unusable.

A brass toilet water supply line is a bit more difficult to deal with than a flexible one. For one thing, brass has a tendency to corrode.

A brass toilet water supply line is a bit more difficult to deal with than a flexible one. For one thing, brass has a tendency to corrode.

A point of reference is that even if your supply line is silver, it is still brass inside. When the brass fittings and pipe corrode, the brass gets delicate. The result is that when you tighten the fittings you may do more harm than good. Sometimes the leak gets worse.

Never try to tighten a leaking line with just one wrench. This is especially true when the fittings are old and corroded. Use two wrenches, one on the fitting you are tightening and the other on the valve or pipe you are tightening to.

For small leaks you can try tightening the fittings. Be careful and don't over tighten. Too much torque and you can make things worse, a little leak becomes a big leak. Go a quarter turn at a time and check to see if it is still leaking. Dry the fitting off with a rag and rub you finger across it. A dry finger should mean no leaks.

If the toilet water supply line is too corroded you will need to replace it. Shut the water off at the water shut off valve. Is the valve old and corroded to? See the article 'Repairing Water Shut Off Valves', for information. With the water off you will want to loosen the fittings. The two wrench thing applies even when you are removing the old one.

Two things you have to do with the supply line. First you have to shape it to the right bends. Use a tubing bender or your thumbs to carefully bend the pipe. Don't kink it. Dry fit the tubing to the flange on the toilet and mark the length to cut it. Use a hack saw to cut the tubing to length.

Get a new nut and ferrule for the end that goes into the valve and a large nut for the closet connection. Make sure the supply line you buy is for a toilet and not a sink, they are different. Put the nut, then the ferrule on the line and start the tubing into the valve. Turn the nut finger tight. Put the nut on the toilet and tighten finger tight. Tighten them down if you are sure they fit. Turn the water back on and check for leaks.

Flexible Supply Lines

A more popular choice in recent history is a flexible line with factory installed fittings. Since the line is flexible you can move it as needed for proper alignment. The fittings screw onto the valve and toilet tank without any additional parts. Simple, less than ten minutes to install one of these.

Toilet water supply lines come in two styles. Plastic lines are less expensive and are usually white. Stainless steel lines cost a little more. The steel lines are still flexible and are a little tougher.

Flexible toilet supply lines have factory installed ends on them. These ends have integral washers built into them, so they are ready to go.

Flexible toilet supply lines have factory installed ends on them. These ends have integral washers built into them, so they are ready to go.

Tightening a Leaking Supply Line

The likely problem with this type of line is a leak at one of the fittings. Tightening them up is usually the solution.

A flexible toilet water supply line is a little easier to tighten. It is still a good idea to use two wrenches. This is just to make sure that you don't damage anything else. Tighten the fitting that is leaking a quarter turn at a time until the leak stops. Use a dry rag and your finger to check for leaks.

Replacing a Toilet Supply Line

Replacing the supply line is pretty easy. Shut the water off before you loosen the fittings. Loosen the fittings and remove the old supply line. See the article on 'Toilet Supply Line Fittings' for information on getting the supply line connected correctly.

Obtain a flexible toilet water supply line that is close to the length you need. Do not get a supply line for a sink, it will not work on a toilet. One end of a toilet supply line is much larger than a sink line.

Start the fittings onto the proper male threads at the valve and toilet. The large end goes under the toilet tank.

Use two wrenches when you tighten the fittings, you don't want put stress on the valve and get it leaking. Tighten up the fittings and check for leaks. That's it, not much to it.

Supply Line Sizes

These lines come in various lengths, such as 9", 12" , 15" and 20". Try to get a length that is slightly longer than what you need. Too long and you will have to loop it under the tank. Not the end of the world, but less desirable.