Pocket Doors

Fixing a Pocket Door Latch

Fixing a pocket door latch will often involve some adjustments to the pocket door. When the door and the strike plate are not aligned correctly, the door will not latch. Sticking or stiff pocket door latches can be lubricated to get working freely.

Fixing a pocket door latch will often involve some adjustments to the pocket door. When the door and the strike plate are not aligned correctly, the door will not latch. Sticking or stiff pocket door latches can be lubricated to get working freely.

For related information, see the articles 'Troubleshooting Pocket Doors', 'Adjusting Pocket Doors' and 'Fixing a Pocket Door Off the Track'.

Pocket Door Latches and Locksets - General Information

Most pocket door locks are not locks at all. They are more like latches. They offer a level of privacy when the door is closed. But it is not that hard to open them from the other side.

A pocket door latch or lockset differs from a normal door lock. A standard door lock has handles or knobs that protrude out of the door. A pocket door has to slide into a narrow pocket that is built into the wall. There is no room for knobs. What do you do?

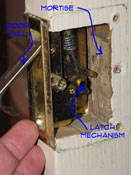

For this reason a special type of latch or lock was designed for this type of door. The lock is flush with the door panel. It has insets in it for a thumb turn or sometimes a sliding mechanism. The thumb turn or slide operates the latch. When the door is closed there is a flip handle that acts as a pull. Otherwise you would not be able to get the door open.

Pocket door locks have similar problems to regular locks. They can become misaligned and the mechanism inside can get stiff. Another thing to note is that a pocket door lock is mortised differently than a standard door. When purchasing a new door slab, you don't want to get one that is bored for a standard door. Simple lubrication and adjustment will solve most problems with this type of lock.

Pocket door locks have similar problems to regular locks. They can become misaligned and the mechanism inside can get stiff. Another thing to note is that a pocket door lock is mortised differently than a standard door. When purchasing a new door slab, you don't want to get one that is bored for a standard door. Simple lubrication and adjustment will solve most problems with this type of lock.

Fixing a Pocket Door Latch - The Issues Involved

What Can You Save? - Lubricating a lock and adjusting a door will take only a few minutes for a carpenter. He will charge you for coming out and this could run $50 to $75. Replacing a lock will run $75 to $100.

How Hard Could It Be? - A pocket door lock is a fairly simple device, most repairs are not hard. These repairs will have a Difficulty Level of: Simple. These repairs require a Skill Level of: Handyman. For and explanation of the terms in this section, see 'How to Use This Site'.

Check the Simple Things! - Lubricating the lock is the simplest thing you can do. A stiff or frozen lock will likely respond to some silicone lubricant.

What Can Go Wrong? - Be careful when you take a lock apart. Losing a part could cause the lock to quit working. Adjusting the door the wrong way can cause the lock to quit working altogether.

Lubricating a Pocket Door Lock

Lubricating a pocket door lockset is not too hard. However, you do have to take the latch apart to get to most of the parts that need attention. Latches and locksets that are sticking or making noise need lubrication.

Before you begin lubricating your pocket door latch you want to have a can of lubricant that is suitable for door locks. A silicone based lubricant is best. You also want to have a rag on hand to wipe up any excess oil.The lock assembly probably consists of three parts. The center latch mechanism.

This mechanism also has the flip out handle that acts as a door pull. The other two parts are the cover plates. Each plate has a thumb screw or slide that operates the latch.

You want to use a good quality silicone spray to lubricate locks. Use the long slender tube that comes with most spray lubricants. Keep a rag handy to wipe up any excess oil.

You want to use a good quality silicone spray to lubricate locks. Use the long slender tube that comes with most spray lubricants. Keep a rag handy to wipe up any excess oil.

Gingerly spray the oil into the moving parts. Work the latch back and forth until it moves freely. Make sure you oil all the parts including the slides or thumb screws. Use the rag to wipe up any excess oil. When you are sure the lock is working properly, you can put it back in.

Removing the Pocket Door Latch

A Pocket door lock is held together with screws. There are probably four screws that are toward the center of the door that hold the lock assembly to the door. Use a screwdriver to take these screws out. The entire assembly should slide out, once the screws are removed.

A Pocket door lock is held together with screws. There are probably four screws that are toward the center of the door that hold the lock assembly to the door. Use a screwdriver to take these screws out. The entire assembly should slide out, once the screws are removed.

The three pieces are also held together with screws. It will be one or two on each side. You probably do not need to take these screws out. With the lock out of the door, you can inspect it to see what your problem might be. If nothing is broken and the lock is just difficult to operate, lubrication is the likely answer. See the next step.

Lubricating the door lock should have taken care of any noise or sticking problems with your latch. We hope this article helped to get your pocket door working properly.

Troubleshooting Pocket Door Latch Problems

Trouble with the latch closing is usually tied to the alignment with the strike plate. Pocket doors can be adjusted, unlike conventional swinging doors. The article 'Adjusting a Pocket Door' gave you instructions on how to get the door aligned properly.

When all else fails, you can replace your latch. There are not a lot of choices with this type of hardware. In the article on 'Replacing a Pocket Door Latch' we covered purchasing and installing a new lockset.

Summary

We hope that this article helped with your pocket door lock. You should have been able to take care of your problem without too much trouble.

So what did you find out about your pocket door lock? Did it just need to be oiled. Many times a little lubrication is all that is needed. Was the strike plate not lining up with the latch? Again a simple adjustment should have taken care of this problem.

Replacing the lock is often done when the old one gets tired looking. This is not a big job either, as long as you get a lock that is the same size. Now that you have completed this task you can look for other home repair projects.

Hopefully you have been able to take care of the issues with your pocket door latch.

Replacing Pocket Door Rollers

Replacing pocket door rollers is not too hard if you have the right ones to replace them with. There are some concerns with attempting to replace the rollers.

Replacing pocket door rollers is not too hard if you have the right ones to replace them with. There are some concerns with attempting to replace the rollers.

Pocket Door Rollers - Standards

You might think that something as common as pocket doors, that there would be some standards. Unfortunately, there are not.

See the article 'Issues With Pocket Door Track', for additional information.

How Pocket Door Rollers Work

Pocket door rollers keep the door running inside of a metal track. The rollers are made of metal and nylon and usually have three or four rollers on each assembly. Regular doors are supported by hinges. The hinges are attached to the side of the door. A pocket door has hangers that are attached to the top of the door with metal brackets. Like any wheel that uses bearings, lack of lubrication can cause them to wear out and start to tighten. When this happens the door becomes hard, sometimes impossible, to move.

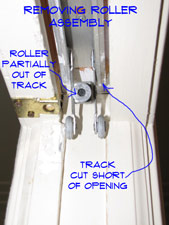

The door rollers need to be able to ride in the grooves in the track. The track is 'C' shaped with the sides curled up to form a groove. The style of roller usually matches the metal track that they ride in. Finding rollers that are an exact match for the ones that you have may be challenging. You can buy kits that have new track included. The problem is that unfastening and installing the track inside the pocket is pretty hard.

Removing Pocket Door Rollers

The rollers and the track need to match, otherwise, they won't work, or they will work very poorly. So you need to make sure you get the correct ones before you remove the old ones.

See the article 'Removing Pocket Door Rollers' discusses how to take off the door and remove the rollers. You might want to get some help, before you attempt to remove the door.

Most of the time, replacing the rollers is not practical or even possible. Lubrication will usually get them working again. See the article 'Lubricating Pocket Door Rollers' for more information. It could be that a little oil will solve your problem.

Replacing the Rollers

With the door removed it is easy to replace the rollers. There is an opening at the end of the support track on the strike side of the door. Tilt the roller assembly into the opening, moving it into the track until the wheels start to roll in the track. Continue to move the roller toward the middle of the door opening, tilting it until the second set of wheels engages the track. Move it into the track until all the wheels are in the grooves in the track. move the roller back and forth to make sure it is working freely.

Move the first roller toward the far side of the door. Repeat the process with the second roller. Again, check to make sure both rollers are working freely.

Putting the Door Back On

Getting the door back on the hangers is a little tricky. See the article 'Putting a Pocket Door Back on Track' for information and instructions.

Lubricating Pocket Door Rollers

Lubricating pocket door rollers is a wise maintenance activity. A little oil installed once or twice a year will keep the door operating correctly.

Lubricating pocket door rollers is a wise maintenance activity. A little oil installed once or twice a year will keep the door operating correctly.

Not sure if this is your problem? See the article 'Troubleshooting Pocket Door Problems' for a complete listing of subjects on pocket doors. Having trouble with the pocket door opening and closting, see 'Replacing a Poc ket Door Off the Track' and 'Removing a Pocket Door' for instructions on what to do.

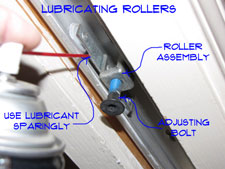

Most doors will have two sets of rollers that glide in the track. The rollers will typically have three or four wheels.With that many wheels it is easy to see how problems could arise.The rollers are not technically part of the pocket door track. They are, however, matched to the track. To keep them working smoothly, you need to lubricate them periodically.

Using the Right Lubricant

You want to use a lubricant that has silicone in it. The wheels are made of nylon and you do not want anything that is too strong or will damage the wheels.

Another concern is making a mess. Do not use grease or any lubricant that does not dry clear. Although the intent is to just put the oil on the rollers and track, it is possible that you will get some on other surfaces. Make sure it is an spray type that can be easily cleaned off of other surfaces.

Formulated with Teflon™ Fluoropolymer to enhance performance. Its clear, non-evaporating formula eliminates wear from constant friction and is safe and non-staining.

Blaster makes some products that are suitable. However, they are not the only ones that can be used. Try to locate a spray lubricant with similar properties.

'Blaster Garage Door Lubricant' is a silicone-based lubricant that leaves a tack-free film that won't accumulate dust and dirt. It effectively helps stop squeaks associated with garage doors and mechanisms. 'Blaster Silicone Lubricant' contains a higher concentration of silicone than competitor brands, which provides longer-lasting lubrication. Both product boast that they won't accumulate dust & dirt and that they quiet noisy operation of moving parts.

Purchasing Lubricant

Most home supply and hardware stores will have lubricants that will work for a pocket door. See the section above on choosing the right type. You can also find them online if you want to purchase a specific one.

A can of spray silicone lubricant should run around $5 to $10 and will last for quite a while. This type of lubricant is good for several household chores.

Cleaning the Rollers and Track

Before you apply any oil, you are going to want to make sure that the rollers are free of dust and dirt. You will also want to make sure that the track is free of dirt and build up.

To clean up the rollers, you will need to remove them. See the article on 'Removing and Replacing Pocket Door Rollers' for instructions on what to do.

Oiling the Rollers

Before you start make sure that you have a can of silicone spray and a rag. The rag will help to keep from getting the oil or spray on other surface. It will also be handy to wipe up any over spray or drips that may occur.

Carefully spray the rollers and the track. Do not use too much, but try and get an even coating. Move the door back and forth to work the lubricant into the nooks and crannies.

If the door still does not operate smoothly, add some more spray until the operation is smooth. If the rollers will not free up, they may need to be replaced, see the article 'Replacing Pocket Door Rollers' for more information.

Summary

Periodically oiling or lubricating the hardware on a pocket door is a good practice. The main moving part for the door is the two hanger/roller assemblies that roll along a track at the top of the door.

Repairing and Replacing Pocket Door Track

Replacing pocket door track is a repair that has some big problems associated with it. Are there replacement kits for pocket door hardware? Yes there are, see the article 'Pocket Door Hardware Kits' for more information.

Getting a kit is not the problem. Being able to install all the components of the kit is the problem.

Make sure that you can not get the door working before you pursue this option. See the article 'Lubricating Pocket Door Rollers' before proceeding. It is rare that a pocket door track would fail. See 'Tightening Pocket Door Track' for information on the one possible failure.

A 'Pocket Door Track' has (3) likely repair issues and (1) difficult choice. If you see your problem here, you can take a quick jump. Otherwise, read the overview below to zero in on your problem.

'Tightening Loose Track' - Since the track supports the weight of the door, tightening them would be a good idea. 'Lubricating Pocket Door Rollers' - The rollers ride inside the track. Sticking, frozen or noisy rollers can be a problem that is fixed quickly.

'Replacing the Rollers' - Find out the issues with matching the rollers to the track. 'Replacing the Track' - This is mostly a list of reasons why you don't want to try and do this. Find out what the issues are.

The pocket door track is found above the door, concealed in the jamb. The track spans the door opening and continues on into the cavity that is created by the pocket door frame. The door slides back and forth along the track. In fact, it disappears neatly into the wall, out of the way.

The pocket door track is sturdy enough to carry the weight of the door. The track can be different, depending on the manufacturer. The main thing to keep in mind is that the rollers are matched to the track. The track has grooves for the rollers to ride along. The weight of the door rests on these grooves via the rollers and hangers.

The track itself does not have any moving parts. Therefore it is fairly sturdy and rarely needs any attention or repairs. The exception to this rule would be when the track is not installed properly. The track needs to be installed securely to the door head. A track that loosens up will need to be tightened up.

What Can You Save? - There is not a lot that can go wrong with the track itself. When it works loose it needs to be tightened. This could run $50 to $75. When the rollers seize up you need to replace the track and the rollers at the same time. This could run $100 to $200.

How Hard Could It Be? - Tightening a loose track is not too difficult for the exposed portion. The hidden section is another story. Replacing a pocket door track is a fair amount of work. It may involve cutting out some drywall to get at the concealed end of the track.

Check the Simple Things! - Try lubricating the rollers before you do anything else, this is the solution most of the time.

What Can Go Wrong? - Replacing the track may involve cutting out some drywall to allow you to get at the screws. Patching drywall is a messy job and you have to paint the wall after your done. This is after you have removed the door and set it aside. This will be more than an afternoon job.

Pocket Door Track - How It Works

The pocket door track is usually an aluminum extrusion. They can be "C", "T", "F" shaped depending on the age of the door and the manufacturer. The important thing to remember is that, the rollers have to match the track.

The rollers run along grooves in the track, allowing the door to slide back and forth. This is what gives you that feature of the door 'dissappearing into the wall'.

The pocket door track is usually installed during the construction phase. When the walls are open, fastening the track is no problem. After the drywall is installed, access to the narrow 'pocket' is severely restricted.

The track is cut short of the door frame to allow for the removal of the pocket door rollers. The track is generally installed with wood screws that go into the head portion of the frame.

Tightening Loose Track

The pocket door track is attached to the head of the frame with screws. The problem with this is that the track is twice as long the door opening. Half of the track is hidden inside the pocket. Making the screws difficult to get to and even harder to tighten.

The first thing to try is to tighten the screws you can get to. Move the door all the way into the pocket and you will be able to see the track. Most pocket door tracks are held in place by five screws. You should be able to get to three of them from the open doorway. See if this tightens the track up sufficiently.

Cutting a hole in the drywall is an option, if you have to get at the concealed screws. Cut a twelve inch long by six inch high hole in the approximate center of the pocket. Cut the hole three or four inches below the top of the door. Try to save the piece of drywall for the patch later. For information on installing a drywall patch, see the article 'Repairing Drywall Holes'. This article has some instructions on how to cut out the patch and repair it afterward.

With the hole cut in the drywall you should be able to get at the screws to tighten them. Move the door out into the opening before you attempt this. You may need a flashlight to see the screws. Make sure the pocket door track is secure before you close up the hole in the drywall. Patch the drywall and paint the wall. That sure is a lot of work to tighten a couple of screws.

WARNING!! A pocket door can be heavy and awkward to handle. Get Help Before Attempting to Remove It!!! WARNING!!!

Replacing Pocket Door Track

If you can get to it, replacing pocket door track is simple. A few screws and that's it.

If you can get to it, replacing pocket door track is simple. A few screws and that's it.

Generally, the length of the track is set by the door size. A 2' 6" door will have have a track that is approximately 58 1/2" long. The length of the track is determined by doubling the door size and then subtracting a relief space of around 1 1/4" to 1 1/2".

The relief space is to get the rollers in and out, once the framework is installed. The track is installed tight to the inside end of the pocket and the relief space is left at the open, strike side jamb.

The track is usually cut to length when you buy the kit. Again, the kits are sized by the size of the door. See the article 'Pocket Door Hardware Kits' for more information on what's available.

Accessing a Pocket Door Track

You do not need to take the door completely apart. You do need to be able to get at the top sixteen inches of the pocket to access the screws.

There is some good news. You only need to get at one side or the other. The bad news is that this will involve cutting out some drywall. The drywall will need to be patched, taped, mudded and painted.

Are you sure you want to do this?

Cutting Out the Drywall

You need a 16" x the Width of Door opening to access the back half of the track. See the articles in the segment on 'Drywall Patching', especially the article on 'Repairing Big Holes in Drywall', for more information. After the patch is installed, you will want to see the article 'Taping and Mudding Drywall' for tips on how to finish the wall.

You need a 16" x the Width of Door opening to access the back half of the track. See the articles in the segment on 'Drywall Patching', especially the article on 'Repairing Big Holes in Drywall', for more information. After the patch is installed, you will want to see the article 'Taping and Mudding Drywall' for tips on how to finish the wall.

Once you have cut out the drywall, you should be able to see the track and get at the screws.

Removing the Track

Now that you can get at it, removing the track is easy. Use a battery drill and bit holder or a screwdriver to remove the screws.

Have someone hold the track before you remove the last couple of screws. No need to damage the floor by letting the track fall down.

Installing a New Pocket Door Track

The track should be already cut to right length for your door size. It should be slightly shorter than the overall length of your header (approximately 1 1/4" to 1 1/2" shorter). Remember, the relief to install the rollers is at the end by the door strike. The track should go tight to the frame at the inside of the pocket.

The track should have holes at the proper locations for the screws. Just follow that pattern.

Align the track in the center of the header. Keep it parallel the entire length of the header. The track needs to be installed with the 'relief area' at the strike side of the door frame. This allows for the installation of the pocket door rollers.

Summary

Did dealing with your pocket door track turn out to be a big problem? That is certainly not good news. The track is durable and normally problem free. Poor installation may have been the reason you had a problem. A lazy carpenter could be to blame.

Seized up rollers would be the other troublesome situation. A lack of maintenance would cause the rollers to tighten and eventually quit working. Maybe you where able to free them up with some oil. What a relief that was. Were you able to find replacement rollers? Or did you have to buy a whole kit. Hope everything turned out well, now for another repair task.

Troubleshooting Pocket Doors

Pocket doors are in their glory when space is tight. Bathrooms, dressing areas, hallways and closets are all candidates for using a pocket door. The key advantage is that the door slides into the wall, out of the way.

Pocket doors are in their glory when space is tight. Bathrooms, dressing areas, hallways and closets are all candidates for using a pocket door. The key advantage is that the door slides into the wall, out of the way.

This leaves the floor area on either side of the wall for other things. No need to worry about leaving an area for the door to swing in. Architects and builders will often use this type of door in locations where space is critical and the swing of a door will interfere with something else.

Do you have another door problem or type of door? See the article on 'Fixing Doors In Your Home' for more information.

How Pocket Doors Are Different

Pocket doors pose special repair problems. They operate differently than the rest of the doors in your home. Standard doors have hinges that are attached to the door frame. A door that slides into a pocket has hangers that are attached to the top of the door. The hangers are in turn attached to rollers that allow the door to slide.

Most of the repair issues will be related to the hangers or the rollers. Rollers as the have small wheels that can tighten up or even seize up, making the door hard and sometimes impossible to move. The hangers affect the alignment of the door. Gaps along the sides or latches that won't work can be traced back to the hangers.

Pocket doors are usually installed during the construction of the home. They have a special frame that has to be built into the wall. The header for a pocket door has to be twice as wide as a normal door. The reason for this is that half of the door opening is hidden in the wall.

The electrical, plumbing and heating utilities have to be routed around the pocket. Since the door has to slide into the cavity, there is no room for other things. It is possible to have a switch next to a pocket door, however, a special shallow box has to be used.

For the above reasons, pocket doors are difficult to add at a later date. A considerable amount of demolitions is involved in getting them installed.

Repairing Pocket Doors – Finding Help

Pocket door repairs are mostly simple and require only a few minutes. Adjusting the door and lubricating it are two common items. Putting the door back onto the hangers is also a common task. Why call a repairman every time you have an issue? You can take care of most things yourself and save some money.

Below you will find some common problems. There is a brief description and a link that will lead you to additional information. Our evaluation sections of the pages will help you to decide if you want to make the repair. The "What Can You Save?" and "How Hard Could It Be?" sections give you a quick overview of the repair. This will help you decide if it is using Common Sense to make the repair yourself.

The "Check the Simple Things First" section will clue you in to easy fixes to check for. Many times something easy will eliminate a problem without the aggravation of an involved repair. In an effort to warn you about what you are in for, there is the "What Can Go Wrong" section. Forewarned is forearmed as they say. Knowing what to watch out for is always helpful.

Troubleshooting Pocket Doors

This page provides a general discussion on pocket door repair issues. Information on adjusting the door is provided along with an explanation of how the adjustments affect the door. Problems with gaps along the edge of the door and latches that don't work are related to the adjustment.

Lubrication is an important maintenance item for this type of door. Find out how and when to provide lubrication.

Pocket Door Rollers

The rollers are the moving parts for a pocket door. Most doors have two roller assemblies with three or four nylon wheels on each one. Stiff or frozen rollers can make the door difficult to move. Follow this link for information on the rollers.

Pocket Door Hangers

The hangers are a threaded bolt with special ends that allow a bracket to slide onto them. The bracket is attached to the door. With a special wrench you can adjust the hanger. These adjustments move the door up and down and change the margins on the side. This link will take you to an article that discusses this topic.

Pocket Door Track

The pocket door track provides the guide for the pocket door to follow. The track is specially shaped to allow for the rollers. The track extends into the pocket and is hidden from site.

Pocket Door Guides

The guides help the door to align properly when it gets near the latch. Without the guides it is difficult to get the door to go into the stops. When this happens you cannot get the latch to work.

The guides are simple and easy to replace and do not cost very much.

Pocket Door Locks and Latches

Pocket doors need to have a way of maintaining privacy. However, the fact that they slide back into the wall makes a conventional door knob useless. Special latches have been designed to work with pocket doors.

These locks have special problems and look completely different.

Removing a Pocket Door

Pocket doors do not have hinges and so taking one off, differs from a regular door. There is a trick to removing them this article will provide the steps needed to successfully take down a pocket door.

Replacing a Pocket Door

When a pocket door is taken off or it gets knocked off its track, it can be difficult to put back in place. Again there is a method that needs to be followed to get the pocket door back on the track.

Pocket Door Summary

Troubleshooting and repairing issues with pocket doors is a simple task most of the time. Replacing the track can be a big job that may even require some drywall patching. Most of the time it is just some adjusting and lubricating. A few minutes work and your door will be quiet and smooth.

Now that you have addressed your disappearing door problems, you are ready to move onto other home repairs. Do you have a list? Or is it a job jar? Whatever your tracking method, you can go to the next item. Unless you have earned a break.