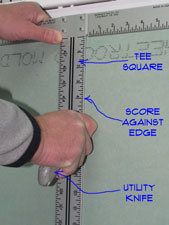

Drywall comes in sheets that are four feet wide. Getting accurate cross cuts can be a little tricky and time consuming. For this purpose, the drywall 'tee square' was developed. It looks like a big tee, one side is four feet long and is used as a guide for the utility knife. The other side of the tee rests against the factory edge of the drywall, thus 'squaring' the cutting guide.

Drywall comes in sheets that are four feet wide. Getting accurate cross cuts can be a little tricky and time consuming. For this purpose, the drywall 'tee square' was developed. It looks like a big tee, one side is four feet long and is used as a guide for the utility knife. The other side of the tee rests against the factory edge of the drywall, thus 'squaring' the cutting guide.

You hold the drywall tee square in place at the desired spot with your hand and toe (or knee). Using the utility knife, you follow the square, scoring the drywall. This speeds up the cutting process and increases the accuracy of the cuts. Drywall usually needs to butt up to other pieces of drywall, so a clean straight cut is important.

A drywall tee square is an important part of the drywall cutting tools line up. You can find them at stores that sell drywall and drywall supplies. A tee square will run around $15 or $20. Probably not worth it if you only have a couple of cuts to make. A bigger job or keeping it in your tool box for future projects will make it worth the investment.

Drywall and Sheetrock Saws

Keyhole Saw

A drywall keyhole saw is a small saw with a blade that comes to a point. The teeth are fairly coarse, making it an effective tool for cutting drywall.

A drywall keyhole saw is a small saw with a blade that comes to a point. The teeth are fairly coarse, making it an effective tool for cutting drywall.

The point can be used to bore into a sheet of drywall to cut out and opening, such as an electric box. It can also be uses to saw notches and other cuts in a sheet of drywall.

The drawback to cutting openings with a drywall keyhole saw is that you have to measure and lay them out on drywall. Then you cut them out before the drywall is installed. Getting accurate measurements requires some skill. Other cut outs, like pipes, have to be cut out ahead of time.

A keyhole saw is an important drywall cutting tool. Most of the time it is a must for a drywall repair project. A keyhole saw will cost between $5 and $10 and will generally last a long time.

Big Drywall Saw

In the days before routers, a big drywall saw was a standard item for a professional drywall hanger. It has heavy blade with large teeth. Originally they had wooden handles. Most of them today have plastic handles, making that a durable tool.

In the days before routers, a big drywall saw was a standard item for a professional drywall hanger. It has heavy blade with large teeth. Originally they had wooden handles. Most of them today have plastic handles, making that a durable tool.

A big drywall saw is used to cut out large openings, like doors and windows, in the drywall. The design of the teeth keeps the saw from binding and will cut through drywall quickly.

You may want to consider this type of saw when you have a lot of cuts to make. For just a few cuts, a keyhole saw will work. A big drywall saw will run around $15. They are not as common as they once were, but they can still be found and drywall supply stores.

For most drywall hangers, the 'Drywall Router' has replaced the big drywall saw. Routers are also capable of making large cuts quickly.

Circle Cutter

When you have a round hole to cut, a drywall circle cutter is the tool of choice. A circle cutter is a compass of sorts. It has a center pin that is pushed into the drywall and a wheel that will score the paper. The wheel is attached to an adjustable shaft.

When you have a round hole to cut, a drywall circle cutter is the tool of choice. A circle cutter is a compass of sorts. It has a center pin that is pushed into the drywall and a wheel that will score the paper. The wheel is attached to an adjustable shaft.

Pipes, light boxes and can lights, all require that round holes be cut into the drywall. Yes you can draw the circle on the drywall and cut them out with a keyhole saw. This tends to be a little time consuming and less accurate.

You set the diameter on the drywall circle cutter to match the size of hole you want. You still have to cut the hole out with a keyhole saw, the circle cutter just makes laying it out quicker and easier. It also scribes the paper on the drywall, giving the saw a path to follow.

A drywall circle cutter will cost about $15. They last a long time and would be considered a good investment for homeowners that are willing to tackle drywall projects. Most stores that sell drywall and drywall supplies will have this tool.

Drywall Router

Do you want to add some muscle to your drywall cutting tools? A drywall router would be just the thing. Routers have streamlined many of the cutting tasks for drywall. In addition, they have dramatically reduced the amount of lay out required to make cut outs.

Do you want to add some muscle to your drywall cutting tools? A drywall router would be just the thing. Routers have streamlined many of the cutting tasks for drywall. In addition, they have dramatically reduced the amount of lay out required to make cut outs.

The main advantage to a drywall router is that it will follow the item that needs to be cut out accurately and neatly. You tack the sheet of drywall in place and then insert the router inside the area to be cut out. You move to the outside of the cut out and then follow the shape with the router. No question, this if very cool!

There are some drawbacks. First, there is the router itself. It is not a standard router that you use for woodworking. It has a special sized collet for the drywall cutting bits. So there is the investment of $60 to $80 to consider. Second, they require some practice to use effectively. You need to learn which way to go to follow an opening. Additionally, you have to learn how to get to the outside edge of items like electric boxes.

Third, there is the mess. A drywall router creates a lot of dust. Drywall dust has the ability to get everywhere in a home very quickly. It is very fine dust and a chore to clean up. You can use a shop vac in conjunction with a router, but this is not a totally dust free solution and extra work.

For a small project, this type of drywall cutting tool does not make a lot of sense. When you have a bigger project or ongoing projects, you may want to consider it. Remember you will need to practice a little, before you start using it. See the article 'How To Cut Drywall', for some tips and tricks on using a drywall router.

Drywall Rasp

A drywall rasp is used to smooth the edges of the drywall once a cut is made. You cut drywall by scoring the paper and then 'breaking' or 'snapping' it.

A drywall rasp is used to smooth the edges of the drywall once a cut is made. You cut drywall by scoring the paper and then 'breaking' or 'snapping' it.

When you do this the gypsum core of the drywall breaks unevenly. The bumps in the gypsum can keep your panels from aligning properly.

The solution to this problem is to smooth the edges. A drywall rasp will do the job nicely. It will cut the gypsum down until it is smooth with the edge of the paper.

A rasp is inexpensive, around $5 to $10. This can be a good addition to your drywall cutting tools.

Stanley makes a rasp that is commonly available and sells for under ten dollars. Wal-Board makes one that is used by professionals that is available most places that drywall is sold.

Why do you need to learn how to cut drywall? Drywall is a common product in most homes. From time to time repairs need to be made or drywall needs to be removed to repair other things. Another scenario might be making a home improvement. Finishing a basement or adding a closet will involve cutting drywall.

Why do you need to learn how to cut drywall? Drywall is a common product in most homes. From time to time repairs need to be made or drywall needs to be removed to repair other things. Another scenario might be making a home improvement. Finishing a basement or adding a closet will involve cutting drywall.

You need drywall cutting tools when you have a drywall repair project. Using the same tools that you use to cut wood on drywall is not a good idea. Drywall is a much different product and therefore, cuts differently. Worse yet, using a power saw on drywall can ruin the saw and make a mess that you would not think possible.

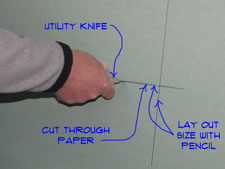

You need drywall cutting tools when you have a drywall repair project. Using the same tools that you use to cut wood on drywall is not a good idea. Drywall is a much different product and therefore, cuts differently. Worse yet, using a power saw on drywall can ruin the saw and make a mess that you would not think possible. Of all the drywall cutting tools, the drywall utility knife is the one that is used the most. Cutting the paper is the key to cutting drywall. You need to 'score' the paper on one side of the drywall first. Then you 'break' the core by folding the drywall back. Next you use the utility knife to cut the second layer of paper.

Of all the drywall cutting tools, the drywall utility knife is the one that is used the most. Cutting the paper is the key to cutting drywall. You need to 'score' the paper on one side of the drywall first. Then you 'break' the core by folding the drywall back. Next you use the utility knife to cut the second layer of paper.