Doors

Fixing Exterior Door Weatherstripping

Why do you even need weatherstripping for doors? Why don't they make the doors so they fit tight and the air doesn't leak? Sounds great on paper, but you would never be able to open or close the door if it was that tight. Doors have a gap around the perimeter. Guess what? Air comes in around those gaps. In the middle of winter it can be very cold air.

Why do you even need weatherstripping for doors? Why don't they make the doors so they fit tight and the air doesn't leak? Sounds great on paper, but you would never be able to open or close the door if it was that tight. Doors have a gap around the perimeter. Guess what? Air comes in around those gaps. In the middle of winter it can be very cold air.

For related information, see the articles 'Troubleshooting Exterior Door Problems' and 'Adjusting Exterior Doors'. Is is possible for your door to be out of adjustment, causing the weatherstrip to not work correctly.

Weatherstripping is used to provide a flexible seal between the door and the frame. It keeps out the cold air. There are many types and sizes of weatherstripping. Some work better than others. They all work on the same principle, they are intended to stop the air leaks.

Over time the seals can go bad or get loose. When this happens the air leaks in again and you need to do something about it. At this point, you are wishing your air conditioner would blow this much cold air in the summer time.

Weatherstripping for Doors - Information

What Can You Save?

A carpenter or a handyman service will need to charge you for coming out. Then you will need to pay for the new weatherstripping and the time it takes to put it in. This will run you between $50 and $100.

How Hard Could It Be?

Dealing with weatherstripping is pretty easy.

Check the Simple Things!

Weatherstripping is fairly simple. Some types are fastened with slotted screws. You may be able to loosen the screws and adjust the weatherstripping.

What Can Go Wrong?

Taking off the old weatherstripping without replacing it with new can leave you with a door that really leaks air. In a real pinch, put some masking tape over the cracks at night.

Weatherstripping for Doors - The Steps Involved

There are three types of weatherstripping that are commonly used on doors. In older homes, you may find metal weatherstripping that had two parts that fit together to form a seal. A common retrofit type is made of foam or rubber. Although this type is easy to install, it also does not last very long.

Newer doors, usually metal or fiberglass may have weatherstrip that fits into the frame of the door. The door pushes up against this type for a nice seal. This type only works on a door the specially mortised to recieve it.

Metal Weahterstripping

Adjusting metal weatherstripping is not difficult and can save a lot on heating and cooling. There are several styles of metal weatherstripping, most of them are adjustable. One type that is sold commonly today consists of an extruded aluminum track with a rubber seal that fits into it.

Adjusting metal weatherstripping is not difficult and can save a lot on heating and cooling. There are several styles of metal weatherstripping, most of them are adjustable. One type that is sold commonly today consists of an extruded aluminum track with a rubber seal that fits into it.

This type usually has slotted screws that allow for some adjustment. First check to make sure that the rubber seal is in good condition. It should still be pliable, not dried out or cracked. It should not be missing portions along the door.

Are you satisfied that the rubber seal is still working? Remember it is the rubber seal that is doing the work. Close the door and stand on the outside. Do you see any gaps between the rubber seal and the door. Loosen the screws and snug the rubber seal up to the door, slightly compressing the rubber. Tighten the screws. Check the entire perimeter of the door in this manner. The weatherstripping should be snug on all three sides of the door. That's all it took, loosening a few screws? Wow, another weatherstripping for doors success story.

You can buy a replacement set for this type of weatherstripping for about fifteen dollars. You need a hack saw to cut it to length. Use the screws that are provided to screw it in place. With the door closed snug the rubber gasket to the door. Run the screws into the slots in the metal track.

Foam Weatherstripping

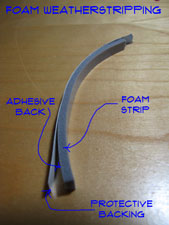

Replacing rubber weatherstripping is not that difficult. This is the kind that is either rubber or foam and has an adhesive strip on the back. There are several configurations of self stick weatherstripping available. Check to see if the original material was thick enough to seal the door. You may need to obtain thicker material if there were gaps. Remove with a scraper weatherstripping that is dried out, missing or cracked.

Replacing rubber weatherstripping is not that difficult. This is the kind that is either rubber or foam and has an adhesive strip on the back. There are several configurations of self stick weatherstripping available. Check to see if the original material was thick enough to seal the door. You may need to obtain thicker material if there were gaps. Remove with a scraper weatherstripping that is dried out, missing or cracked.

Packages of this type of weatherstrip come with enough material to do one door (17 lineal feet). Don't mess around, replace it all when you do it. Take a piece with you to obtain a similar product. The important feature is the thickness. It has to be thick enough to fill the gap and be compressed when the door is closed. Material that is too thick will interfere with the operation of the door.

Peel the backing paper off the new weatherstripping and press it into place, starting at one end and working to the other end of each side of the door. This stuff can be a little frustrating, take your time. Working with a wet noodle comes to mind. Use a utility knife to trim the excess. Close the door and check to see if you have a good seal all the way around the door. Everything looks good? Then you have mastered all the skills needed for dealing with weatherstripping for doors issues.

Integral Weatherstripping

Replacing integral weatherstripping occurs when it has worn out. Integral weatherstripping is the type that seems like it is built right into the door frame. Actually, it is very easy to change.

Replacing integral weatherstripping occurs when it has worn out. Integral weatherstripping is the type that seems like it is built right into the door frame. Actually, it is very easy to change.

Newer homes (say the last twenty years or so) may have exterior doors that have the stop rabbited into the door jamb. The door jambs are 5/4” material on the stop side of the frame and 3/4” on the door side. At the step there is a slot cut into the frame that provides a place for a specially made weatherstrip to be inserted. This is great stuff.

To remove it, you just firmly pull it out of the slot. No glue or screws. It is sold in 7' lengths at most lumber and home stores. You can replace one side or all sides as needed. White and black are the two available colors. Cut the length about a half of an inch long and install it. Use a utility knife to trim it as needed (sharp blade, be careful).

Summary

For related information, see the articles 'Troubleshooting Exterior Door Problems' and 'Adjusting Exterior Doors'. Is is possible for your door to be out of adjustment, causing the weatherstrip to not work correctly.

Repairing or replacing weatherstripping for doors is not too hard of a job. By now your door should be sealed up and you should be warm or cool, depending on the season, with no drafts from your door. Well done.

Removing Pocket Door Rollers

There are a couple of might make sense. One is that, it is easier to lubricate and free them up when they are not up inside the track.

There are a couple of might make sense. One is that, it is easier to lubricate and free them up when they are not up inside the track.

The other is that you might think that running down to the home supply store and getting new ones is the easiest course of action. It could be, if you can find ones that match.

The article 'Troubleshooting Pocket Doors' has all of the topics related to this subject. If this is not your problem, try this link.

Pocket Door Hardware Concerns

One thing you need to realize is that there are no standards for pocket doors. Every manufacturer has different configurations for the tracks, hangers and rollers on pocket doors. Even the same manufacturer may offer multiple styles or change the configuration over time.

The Warning here, is that the rollers much match the track that is installed in the pocket door frame. They are usually not interchangeable.

About now you are saying, 'OK, I'll just replace the track'. Not a good idea most of the time. Replacing the track will usually involve tearing a wall apart and not be worth the trouble. Try to work with the rollers you have, or go online and try to find matching ones (not impossible, just tedious).

Removing a Pocket Door

You cannot remove the rollers without taking the door off. To take the door off you will need to release the door from the hangers.

Different pocket doors will release differently. Some have a slide stop that you push back. Others will have a spring loaded catch that needs to be pushed back to release the door. See the article 'How To Remove a Pocket Door' for more information and instructions.

Some doors will slide off the hanger sideways, others will drop down. An older door may stick a bit, so be patient.

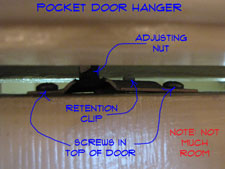

There is a retaining clip that holds the bracket, that is attached to the door, to the hanger. Release the retention clip over and the door, along with the bracket, will slide off the hanger. Pick up the door and angle it, working it out of the opening. When the second hanger is in the door opening you can remove the door from it.

There is a retaining clip that holds the bracket, that is attached to the door, to the hanger. Release the retention clip over and the door, along with the bracket, will slide off the hanger. Pick up the door and angle it, working it out of the opening. When the second hanger is in the door opening you can remove the door from it.

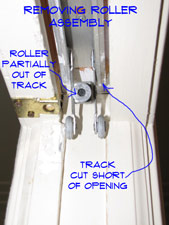

Removing Pocket Door Rollers

With the door removed it is easy to remove the rollers. Roll the first one to the end and allow the wheels to drop down through the opening at the end of the track. Tilt the roller assembly downward, moving it forward until the second set of wheels drops down through. Repeat the process for the second roller assembly.

With the pocket door rollers removed, you can take measurements to find a matching set. You can also take them with you to the supply store to find ones that match.

Using a Pocket Door Wrench

You need a pocket door wrench when you work on you pocket doors. The thin profile will fit in the tight space above the door. You use the wrench to adjust the bolts on the pocket door hangers up or down.

For all the information on 'Pocket Doors' see the article 'Troubleshooting Pocket Doors'.

The wrench is similar to the tools you get with a put together furniture item. As a result, they often get lost. Do you know where your pocket door wrench is? What can you do if you don't?

Locating a Pocket Door Wrench

The first thing you want to try to do is find the wrench that came with the hardware for your pocket door. It is a small thing wrench that can be straight or may have a funny bend in it. It was in the bag of hardware that came with your pocket door. Check the tool and junk boxes.

It may be that you never had it. The builder that installed the door may not have left it for you. Or your house has changed hands a few times and the wrench is in the previous owner's tool box.

Purchasing a Pocket Door Wrench

Now that you need one you probably think it is a simple matter to just buy one. There are a couple of problems with this. First, there is no standardization for pocket door hardware. As a result, each manufacturer will use a different adjustment wrench.

To make matters worse, even if you know the manufacturer of your pocket door hardware, not many of them sell the wrenches by themselves. They will come in a kit.

Try to determine what brand of pocket door hardware you have. With that information you can search online for the wrench. Johnson Hardware and manufacturer of pocket door hardware does sell an adjustment wrench, try this link 'Johnson Pocket Door Wrench'. However, other popular manufacturers such as Stanley do not sell the wrenches individually.

You could purchase the entire kit, just to get the wrench. This will set you back $10 to $20 just to get the wrench.

Adjusting a Pocket Door Without a Wrench

It is possible to adjust the pocket door without the wrench. There are a couple of things you can try.

Using Needle Nose Pliers

They make needle nose pliers that have an offset nose on them that you should be able to get for less than ten dollars. If the door is not too tight, you might be able to get these to work. See the article 'Adjusting a Pocket Door' for information on how to make the adjustments.

Taking the Door Off the Hangers

Another option would be to take the door off the hangers to make the adjustments. This is obviously going to be more work. You may have to take the door down a few times before you get it right.

See the articles 'Removing a Pocket Door' and 'Adjusting a Pocket Door' for more information.

Using a Pocket Door Wrench - Summary

Hopefully you were able to locate your pocket door wrench and make the needed adjustments. If not, there are other ways to solve the problem. With a little extra effort you should have been able to adjust your door.

Repairing Bypass Closet Doors

Repairing Bypass Closet Doors

Bypass closet doors were very popular for use in closets, a few decades ago. You still see them in many homes and some homeowners prefer them to bifold closet doors. These are also called sliding closet doors. 'Bypass' or 'Sliding' the idea is that one door moves in a straight line, in front of or in back of the other door. Unlike normal doors, this type has no hinges.

Instead of hinges they have hanger – roller assemblies, that are attached to the top of the door. The rollers follow a track that is mounted to the head of the door frame. The rollers ride on a metal track the full length of the closet opening

Bypass closet doors, as the name implies, pass by the other door. This is the main drawback to sliding doors. Only half the closet is visible when one of the doors is open. There must be an unwritten law that states that the thing you are looking for will always be on the hidden side of the closet. Bifold doors have increased in popularity in recent years. One of the reasons for this is that they open completely, not hiding anything.

Issues with Bypass Closet Doors

You may have guessed that the door hangers – rollers are the main trouble spot. When the door comes out of the track it can be hard to move and will scrape the floor. Some types of track are more prone to this problem. Learning how to put the door back on track can save calling a repairman.

The hangers are also where you adjust the door. There is an adjustment nut on each hanger. the height of the door and the margins on the sides can be adjusted by these nuts. There are guides at the bottom of the doors. These will keep the doors in alignment as they move back and forth. When the doors get outside the guides they will not move correctly.

Finding Help With Bypass Closet Doors

There are three main issues this type of closet door. (1) The lubrication of the rollers is important. When the rollers start to tighten the door will be hard to move. Trying to force the door will cause it to jump off the track, making the situation worse.

(2) Putting the doors back in the track or guides is a common problem. The door may be impossible to move when it is off the track. It could also fall if both hangers pop out of the track. (3) Adjusting the door is another concern. You may notice uneven gaps on the sides of the doors or the door may rub the floor or carpet when it moves. When this happens, adjustment is the only answer.

Repairing Bypass Closet Doors Summary

Did you learn what you needed to know about bypass closet doors? Most of the problems are pretty easy to fix. Lubrication and adjustment are two common problems. You can do this in just a few minutes.

Putting the doors back on track is another repair that needs to be done regularly. This can involve lifting the door, hopefully, you had some help. The article on repairing sliding doors should have given you all the information you need. Time to move onto your next home repair job.

How To Replace a Door Frame

Replacing a door frame may not be as hard as it sounds.