Drywall

Spackle Tools

Knowing which spackle tools to use is helpful when you are getting ready for a painting job. Spackling is applied to dents, dings and holes in your walls that need to be painted. Applying spackling with the right tools only takes a few minutes.

For related articles see 'How To Spackle Drywall', 'Patching and Repairing Drywall' and 'Taping and Mudding Drywall'.

Putty Knives

A putty knife or spackling knife is a flexible flat blade with a handle on it. It is uses for spreading the spackling onto the wall or ceiling in a thin layer. These knives are typically from 1" to 3" wide. They can be made from either plastic or metal.

For small holes and dings in walls and ceilings a 2" or 3" putty knife will do the job. The plastic ones are inexpensive and work great for small or infrequent projects.

Trowels

Drywall knives or trowels are wider than putty knives and are needed for wider joints. These knives are more expensive and are only needed when you have bigger patches to deal with. See 'How To Patch Drywall' for more information.

Sanding Sponges

Sanding sponges are a great innovation for the home repair culture. The are fairly inexpensive, versatile and very effective for a wide variety of home repair projects. When is comes to spackling and drywall repairs they are perfect.

A sanding sponge is a spin off from a concept that has been around for a long time. Sanpaper works very well for sanding a variety of surfaces. One drawback to sandpaper is the need to keep it flat on flat surfaces. Attaching the sanpaper to a block was the solution. The sanding sponge, takes this concept another step.

Using synthetic materials, a sanding sponge provides the shape of a sanding block along with a flat sanding surface. For semi soft surfaces this has turned out to be an excellent product.

Drywall compound, spackling compound and a variety of other surfaces respond well to the abrasion provided by sanding sponges. Gypsum is a fairly soft material, so it is well suited for sanding sponges.

For information on sanding sponges see the article, 'Using Drywall Sanding Sponges'.

Sanding Blocks

The idea of a sanding block has been around as long as we have had sandpaper. Sand paper is a versatile product that has many uses. The one drawback is that it is very flexible. When you sand spackling, you need to keep the sandpaper flat. A sanding block is the ideal choice.

There is a tendency when you sand with sheets of sand paper to put grooves in the surface. This creates and uneven surface.

Sanding Screen

Drywall sanding screen is a popular way to sand drywall and spackling. It comes in precut sheets that fit onto a speacial sanding block. For larger amounts of sanding, this is a better choice.

Another advantage is that you will get less grooving when you sand. This means a flatter smoother surface. For coplete information on purchasing and using sanding screen, see the article 'How To Use Drywall Sanding Screen'.

Vacuum Cleaner

Dust is a big problem when working with spackling and drywall. There are methods that can eliminate or reduce the amount of dust created. See the article 'Dustless and Wet Sanding Drywall' for more information.

A shop vac is useful for cleaning up the dust when you sand your spackling patches. For small quantities you can use the hose attachment on a regular vacuum cleaner.

A word of caution. Drywall or spackling dust is very fine and can clog the filter quickly on a vacuum cleaner. You may need to change or clean the filter if you vacuum up very much dust.

How To Spackle a Wall

Do you know how to spackle a wall? If you are trying to get the bedroom painted and your son's truck has made some significant dents in the wall, it could be.

Do you know how to spackle a wall? If you are trying to get the bedroom painted and your son's truck has made some significant dents in the wall, it could be.

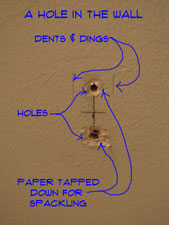

Spackling paste or putty works best for small holes, dents and dings that have not compromised the paper on the drywall or the drywall itself. Is the paper damaged? Is the core of the drywall damaged? Yes to either one. Go to the article on 'Drywall Patching', for instructions on using mud and tape to patch drywall.

Are the holes small, perhaps from picture hangers or nails? If you have dents are they less than a quarter of an inch deep? Then spackling should take care of the problem.

What is Spackle or Spackling?

Spackling paste, compound or putty is a common product that you will find at hardware and home stores. It is a gypsum based product that usually comes premixed and has a consistancy similar to drywall compound. It comes in small cans and is often found near the painting supplies.

There are some popular brands that have been around for years and are easily recognizable. Manufacturers in a effort to sell more products and increase the cost have come out with several options. Vinyl spackling 'Fast Drying Spackling, spackling that changes color as it dries. If you read the labels, just about everyone will offer some special features that make it better than the competition.

Spackling is used to fill small dents, dings and holes in your plaster or drywall surfaces. This is done prior to painting to rid the surface of blemishes. Spackling will often require more than one coat with some drying time in between. Prior to painting the spackling will need to be sanded.

For what it does, spackling is kind of expensive. You can pay $3 to $10 for a small can. When it is kept sealed it will last for a long time, so you do not need to purchase it every time you paint.

There are a few tools you will need to use when you are using spackling. Most of them you will already have on hand. See the article 'Using Spackle Tools' for more information.

How long does it take spackling to dry? This is an important question, especially when you are trying to get a painting project completed. See the article 'Spackle Dry Time' for more information on how long you will have to wait before you can paint.

How to Spackle Drywall – The Steps Involved

Step One - Preparing the Surface

Before you can apply a first coat of spackling, you need to prepare the surface. This is not a difficult job, but it is important.

The first thing you want to do is give the spackling paste a place to go. Especially when you are filling screw or nail holes you may find that there is a burr around the hole. Take the corner of your hammer and gently tap the paper down until you have an indentation. Not too hard. Check it with your finger, no lumps? Feels like a depression? Good.

Select a knife that is larger than the hole or dent you are trying to fix. For a one inch wide dent, use a three inch knife. You want the edges of the knife to be riding on  the smooth surface of the wall. There are no absolute rules here, as long as the knife is wider than the hole. It might be a lot wider.

the smooth surface of the wall. There are no absolute rules here, as long as the knife is wider than the hole. It might be a lot wider.

Step Two - Applying a First Coat of Spackling

With your dent or hole properly detailed you want to put enough spackling paste on the knife to fill the hole. You want to pull the knife across the indentation, completely filling it with paste. For a nail or screw hole, try and work some of the paste deep into the hole. Drag the knife tight against the flat surface of the drywall. Do not build the paste up above the surface of the wall. One even stroke should do it once you have the hole filled with spackling.

With your dent or hole properly detailed you want to put enough spackling paste on the knife to fill the hole. You want to pull the knife across the indentation, completely filling it with paste. For a nail or screw hole, try and work some of the paste deep into the hole. Drag the knife tight against the flat surface of the drywall. Do not build the paste up above the surface of the wall. One even stroke should do it once you have the hole filled with spackling.

How does it look? Do you see any voids? Give it another pass with a little more material if you see voids. The dent or hole should be filled and flat or even with the adjacent wall. Satisfied? Now this is important. Step Away From The Spackling. Walk away and do not touch it until it dries. Check the can for drying time, but remember the more compound you use, the longer it will take to dry.

Step Three - Applying the Second Coat of Spackling

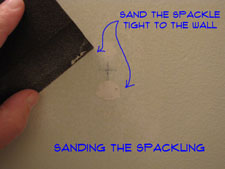

Why would you need to apply a second coat of spackling? Even the best products will shrink, especially when they are filling a deep hole. When the spackling paste is dry you can lightly sand it with a sanding sponge or sandpaper. Sand it flat with the wall surface around it.

Why would you need to apply a second coat of spackling? Even the best products will shrink, especially when they are filling a deep hole. When the spackling paste is dry you can lightly sand it with a sanding sponge or sandpaper. Sand it flat with the wall surface around it.

Apply another thin coat of spackling to the repair. Remember to keep it tight with the adjacent surface. Does it look good? Yes, then Step Back From The Spackling. Do not touch it, let it dry. It should not take as long this time.

When it is dry you can lightly sand it again. Remember the idea is to blend it into the surface around it. Don't sand grooves into it with your fingers. A flat sanding sponge is the best thing to use. For bigger dents and holes you may need to add a third coat. You don't want to see the patch after you paint. If you do, you'll still have a spot that needs repair.

Step Four - Finding Other Spackle Problems on Your Walls

Spackling multiple holes while you are at it, is just an efficient way to do it. Generally, you have some drying time and clean up with spackling. So why not make the best use of these steps and go through and hit all the locations you can find at once.

So if you have more than one spot that needs spackling. Do the first coat on all the spots at the same time and repeat the second and third coats for all the spots. Usually you can go around and hit all the spots in a room in a few minutes.

Let them dry and then hit them again. You will be much happier with the results if you take the time to properly prepare the walls. It's not rocket science but learning how to spackle drywall can be rewarding.

It is pretty aggravating when you finish painting the wall and you see dents and dings that you did not repair. The little bit of time it takes to spackle is well worth it.

Step Five - Sanding Spackling

After the spackling is completely dry, you want to sand it smooth. The idea is that you want it flush with the wall or ceiling surface and smooth to the touch. Sand lightly with a sanding sponge until the surface is ready for paint.

If you feel a depression, you need to apply another coat of spackling paste to fill it.

For more information on methods and best practices for 'Sanding Spackle', follow this link.

Alternatives to Spackling Paste

Spackling paste, putty or compound is sold in small cans that tend to be expensive. The formulas for the material are mostly gypsum and water. With that said, it is safe to say that spackle or spackling is not much different than drywall compound.

Can you use drywall compound in place of spackling? Yes you can. Drywall compound was used to finish all of the seams and joints in your home and it provides an excellent surface for painting. If you already have some on hand, there is nothing wrong with using it instead of spackling paste.

Drywall compound is cheaper than spackling and come in both ready mixed and dry forms. For patching walls, including spackling, there are fast set types they dry in as little as fifteen minutes.

How To Repair Drywall

Knowing 'How To Repair Drywall' can save you time and money. The drywall you need to fix will likely fall into one of four categories, patching large and small holes in drywall,smoothing or fixing uneven drywall, repairing cracked drywall and installing new drywall in place of old damaged material. Although the materials are similar, the techniques vary a little

Knowing 'How To Repair Drywall' can save you time and money. The drywall you need to fix will likely fall into one of four categories, patching large and small holes in drywall,smoothing or fixing uneven drywall, repairing cracked drywall and installing new drywall in place of old damaged material. Although the materials are similar, the techniques vary a little

There are descriptions below for all of the problems you may be having with your drywall or sheetrock. There is even a section dealing with 'moldy drywall'. Also there are links to 'how to' articles that will give you tips and tricks on getting a professional finish.

Finding and Fixing Drywall Problems

Below you will find some common problems you are likely to have with your drywall. There is a brief description and a link that will lead you to additional drywall information.

You have dents, dings and small holes in your drywall, that you want to fix before you paint.

This is a common problem. Hanging pictures, bumping into the walls with furniture, children playing, can leave you with a lot of imperfactions in an otherwise good wall.

To solve this problem you need to do a small amount of preparation and then apply spackling. Keeping the surface smooth for painting it the key. See the article 'How To Spackle a Wall' for complete instructions and information on the best material to use.

There is a hole in your wall the size of a fifty cent piece.

A hole that is larger than diameter of a pencil is probably too big to fix with just spackling. The spackling may fill the hole, but when it dries it will crack and pull away from the edges, leaving a blemish on your wall.

Most of the time fixing smaller holes (1 1/2" in diameter or less) in drywall or sheetrock can be accomplished with just some drywall tape and compound. Its a bit more work than spackling, but not that hard. See the article 'How To Patch Small Holes in Drywall' for more information and instructions on fixing the hole.

A piece of furniture put a big hole in the wall when it was being moved.

You have a hole in your wall that a small animal could crawl through, this is not good. Big holes in a drywall wall or ceiling require some additional steps to fix. Tape alone will not bridge a large gap effectively.

Solving this problem will require that you cut out some of the drywall or sheetrock and install a replacement piece. This is not as hard as it sounds. The article 'How To Fix a Large Hole In Drywall' will provide you with all the steps and complete instructions.

There is a crack in the wall, possibly above a doorway or there is a crack in the ceiling.

Cracks are a common problem and they can be unsightly. They often occur at stress points in the structure, above doors, near stairways, ceilings that change direction to name a few. There are no rules when it comes to cracks, they can happen anywhere.

Just putting some spackling on the crack will not fix the problem. You need a flexible membrane to bridge the two opposing surface together. Often this can be drywall tape.

To learn the proper way to repair cracks in your drywall walls and ceilings, see the article 'How To Repair Drywall Cracks'.

I have an ugly water stain in my ceiling, what can I do?

It may have not even been a leak, maybe a bathtub or toilet overflowed and water got down and dripped onto the ceiling or wall. After it dries you are left with an ugly spot that can be problematic. Paint alone will usually not stop the problem.

If you do have a leak, you want to fix that first before you try and repair the drywall. The severity of the water damage and whether or not the drywall has gotten wet repeatedly will affect how hard it is to fix. It may be as simple as using the right sealer and repainting.

For complete instructions and the materials needed to deal with the problem, see the article 'Repairing Water Damaged Drywall'.

My wall is uneven, sometimes I see shadows when the light is right.

There can be several reasons for this problem. The contractor that did the drywall in your house may have done a poor job. More likely, the wall or ceiling was patched and they did not do a good job of blending in the patch. Whatever the reason, you can eliminate the uneven finish by skimming the wall with drywall compound.

Skimming involves a wide joint knife and a thin layer of drywall compound. The article 'Skim Coating Drywall' has instructions for accomplishing this task.

I have black mold on my drywall. Is this dangerous? What can I do?

Black mold has gotten a lot of attention in recent years and with good reason. It can be a serious health risk, especially for the young and the elderly.

Not all black mold is dangerous, but it takes testing to tell the difference. So assume the worse when dealing with mold. Mold is happens when you have two main ingredients, moisture and organic material. You will need to deal with both the mold and the source of the moisture to get rid of your problem.

The articles 'Is Black Mold Dangerous' and 'Drywall Mold Removal' will give you some guidelines and methods for eliminating the problem.

I have texture on my wall or ceiling and it needs to be patched, is this possible?

There are lots and lots of different textures that are used on drywall. Most of them fall into a handful of groups, each group having distinctive chareteristics. The materials uses and the individual installer can also affect the way a texture looks.

It is possible to patch them, but it may involve a bit of trial and error. The first thing you want to do is identify the type you have and then take steps to replicate it. See the article 'Texturing Drywall' for a complete discussion.

Drywall Repair Articles by Topic

Drywall Patching

Drywall patching involves varying levels of work. At the easy end, you have minor dents and dings that only need a little spackling. The other end of the spectrum is a large hole in your wall or ceiling that needs a new piece of drywall. Taping and finishing will be involved. This job will take a few days and involve several steps.

Drywall patching involves varying levels of work. At the easy end, you have minor dents and dings that only need a little spackling. The other end of the spectrum is a large hole in your wall or ceiling that needs a new piece of drywall. Taping and finishing will be involved. This job will take a few days and involve several steps.

How To Spackle a Wall

Spackling can take care of most small imperctions in your walls and ceilings. There is some minor preparation required to get a good job. Also, more than one application may be required.

Drywall Crack Repair

Of course cracks are unsightly and undesirable. Fixing them involves some drywall tape and compound. There is some preparation that is also required.

How To Patch Small Holes in Drywall

To patch small holes in drywall or sheetrock, you need some tape and compound. It will involve a few steps and some sanding. Done correctly, you will never know that the hole was there.

How To Fix a Large Hole In Drywall

Got a hole in your wall that the cat can crawl through? You are going to need more than tape and drywall mud to fix it. Installing a drywall patch is not that hard, but needed for larger holes in drywall.

Drywall Ceiling Repair

Drywall ceilings have some of their own issues. The size of the drywall may be different. You could have insulation above the drywall. Not to mention the fact that you have to get up on a ladder to get to it. Follow the link above for some tips on how to repair drywall when ceilings are involved.

Repairing Water Damaged Drywall

How do you repair water damaged drywall? Of course the first thing you need to do is correct the leak that caused the water damage. After that you need to determine what level of water damaged drywall you have. It may be as simple as using the right kind of paint or it may involve some drywall replacement. The article , gives you guidelines on how to repair drywall when something has leaked.

Drywall Mold Removal

Oh no! You see some mold. What do you do? Mold as a rule is a sign of a more serious problem. Why do you have mold? Where is the moisture coming from? You need to get rid of the mold, but at the same time you need to address the moisture problems that allowed it to grow. Take some time and review the article on, for information on how to repair drywall when mold is involved.

Is Black Mold Dangerous?

You should know the facts, this can be a serious condition. It is not an insumountable problem, just one that deserves a 'healthy respect'.

Plaster Wall Repairs

Plaster is similar to drywall, yet different. Plaster is made from gypsum, the same as drywall or sheetrock. The big difference is that drywall has a paper facing and plaster does not. The good news is that plaster can be repaired with the same products and tools that you use for drywall. Once the repair is painted, you will never know the difference. This article will provide the needed skills.

How to Cut Drywall

Why do you need to learn how to cut drywall? Drywall is a common product in most homes. From time to time repairs need to be made or drywall needs to be removed to repair other things. Another scenario might be making a home improvement. Finishing a basement or adding a closet will involve cutting drywall.

Why do you need to learn how to cut drywall? Drywall is a common product in most homes. From time to time repairs need to be made or drywall needs to be removed to repair other things. Another scenario might be making a home improvement. Finishing a basement or adding a closet will involve cutting drywall.

Depending on the situation and the type of drywall the way you cut it can vary. This article discusses the ways you can cut drywall with the tools you have at your disposal.

For related drywall repair topics see the articles 'How To Fix Drywall', 'Patching Drywall', 'Repairing Large Holes in Drywall' and 'Taping and Mudding Drywall'.

I do mention some special tools for completeness, but most homeowners will not possess them or have access to them. You do not need special tooling to cut drywall. They just make it faster when you do it all the time. The right tool for the cut you are making is also discussed.

How to Cut Drywall - Information

This article on how to cut drywall is informational. It is intended to provide basic how to skills to get a job done. We do not classify this information as a repair. We provide you with information about materials and techniques. The information below gives you a summary of the various things involved.

Types of Drywall

Learning how to cut drywall depends a little on the type being cut. It is possible for you to have four or more different kinds of drywall in your home. Most of these types cut in a similar way. This is with the exception of cement board which is not really drywall at all. This material is used in bathrooms because it does not rot. Knowing the types will help you when you learn how to cut drywall.

The following is a list of common types of drywall found in residential construction:

- 1/2" Regular Drywall - This is probably the most common type you will find. It is used on most of the walls and ceilings. It is made of a gypsum core sandwiched between two layers of heavy papers. This type is the easiest of all to cut.

Tools Needed: Utility Knife; Keyhole Saw; Tape Measure;

Optional Tools:Tee Square; Router

- 5/8" Firecode Drywall - This drywall is thicker than the half inch material. It also has a special gypsum core that resists heat and provides fire protection. The heavier fibrous core is harder to cut but still possible.

Tools Needed: Utility Knife; Keyhole Saw; Tape Measure

Optional Tools:Tee Square; Router

- Moisture Resistant Drywall - As the name implies this drywall is used for areas like bathrooms that have higher humidity. Sometimes called green board (it comes in different colors now depending on the manufacturer), it is in between regular and firecode for difficulty.

Tools Needed: Utility Knife; Keyhole Saw; Tape Measure

Optional Tools: Tee Square; Router; Circle Scribe

- Glass Mat Drywall - This drywall is a variation of moisture resistant drywall. With the prevalence of mold issues, glass mat drywall was developed to eliminate mold growth on the drywall. The facing is made of fiberglass instead of paper. Mold will not grow without organic material present. You may find some of this drywall in a newer home.

Tools Needed: Utility Knife; Keyhole Saw; Tape Measure

Optionals Tools: Tee Square; Router; Circle Scribe

- Cement Board - A further step in moisture resistance. This is not drywall at all (drywall is made of gypsum, cement board has no gypsum in it).It is made by sandwiching a special cement core between two layers of fiberglass mat. This material is used behind ceramic tile and marble for high moisture areas. This material is the hardest of all to cut.

Tools Needed: Tape Measure; Diamond Circular Saw Blade; Circular Saw

Optional Tools: Tee Square; Router; Carbide Router Bits

The types of drywall listed above may be found in your home. Many homes only have one or two kinds. Don't be shocked if you find something you are not familiar with. The cutting methods below will tell you which methods are appropriate. In addition we will discuss which tools to use for each cut. Learning how to cut drywall is not that difficult when you know a few tricks.

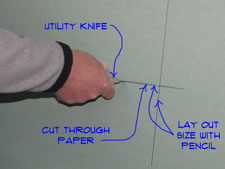

Using a Utility Knife to Cut Sheetrock

Using a utility knife to cut drywall is the your first choice. The drywall has a paper facing on it, that the utility knife is well suited to cut.

The first thing you will need to do when you cut drywall is to size the piece. A tape measure and utility knife are the tools for this. For a patch where you are fitting into a cut out you want to size the piece 1/8" to 1/4" smaller than the hole you are filling. Get your measurements for the piece first. If you want use that old carpenter rule, measure twice, cut once.

To begin your cut you score the paper on the face side of the drywall. For a piece that is close to four feet wide you want to cut clear across the four foot dimension of the drywall. After you have done that you break the piece back and cut the paper on the back side. Repeat this step to size the piece the other way.

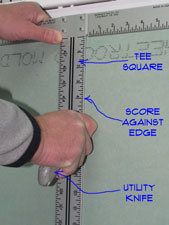

Keeping cuts straight when using a utility knife to cut drywall can be challenging. How do you do it? Great question. There are a couple of ways to do that. You can draw a line on the face layer with a straight edge and a pencil. Then you carefully follow the line with the utility knife. The next option would be to mark the sheet and then use a metal straight edge or a tee square to guide the blade. See the article 'Using a Drywall Tee Square'.

Another very effective method is the one used by professional drywall hangers. You hold the end of the utility knife against the end of the tape measure and hold it in place with your thumb and forefinger. Then you pinch the tape measure at the correct dimension with your other thumb and forefinger. You run you finger along the edge of the drywall and score the board at the same time. You need to keep the tape more or less perpendicular to the side you are measuring from.

This method requires some practice and may not be practical to learn if you only have one or two pieces to cut. Want to try it? Use some scrap pieces to develop your skills.

When you are cutting a small piece out of a larger sheet you will need to use the keyhole saw (discussed below). Cut the drywall with the keyhole saw in one direction and score it and break it in the other one.

Cutting Holes With a Keyhole Saw

Using a drywall keyhole saw for cutting out boxes and openings is common. A keyhole saw as the name implies cuts drywall by sawing it. It has a sharp point that can be bored through the drywall to start a hole. Once the saw is through the drywall you saw along the line. At times you can use a keyhole saw to cut in from the edge of a sheet.

Another thing a keyhole saw is good for is cutting out an opening. Electrical boxes or light fixtures are a good example. You need to measure from the edges that the drywall piece will abut to.

Lay out the opening on the new piece of drywall. With the lines in place you can cut out the opening using a drywall keyhole saw. Use the point to bore into the drywall. Saw the opening out from there.

Some pieces of drywall may need several things cut out of them. Bathrooms and kitchens are examples of this. Using a drywall keyhole saw is a must at these locations.

Using a Drywall Tee Square

When available, using a drywall tee square to cut drywall is a time saver. A tee square as the name implies looks like a tee. It is designed to provide a guide for cutting long sheets of drywall to the desired lengths.

The long leg on the tee square is four feet long. The tee at the top aligns with the long edge of the drywall. The self squaring feature gives you a good edge to cut the drywall along.

Use your knife or a pencil to mark the desired length of the piece you need. Position the tee square at the mark. Use hands, knees and feet to hold the tee square in place while you run the utility knife along it. Snap the drywall and score the back to complete the cut.

Using a drywall tee square as a straight edge to make smaller cuts also makes sense. A tee square is not a big investment, around $20. Weigh the cost against how often you will likely use it. Are you in this home repair thing for the long haul? It might be worth the investment.

Cutting Electrical Outlets With a Router

Cutting drywall with a router can save time and improve the quality of the installation. One note of caution, they generate a lot of dust and can require a lot of clean up.

Drywall routers are not quite the same as a router you may have in your wood shop. They are similar to a laminate router that is a specialized tool. Standard drywall router bits require an eighth inch shank. Heavy duty bits may be a quarter inch shank. The point is that a standard router is not set up to act as a drywall router.

When you get down to the nitty gritty, a standard router might be converted to a drywall configuration. That is beyond the scope of this article. It is possible but not practical. Instead of cutting drywall with a router, I recommend using more conventional cutting techniques for simple repairs.

Drywall routers will cut around an opening when the drywall is in place. When you use a router to cut an opening you first mark and approximate center of the opening on the drywall. Then you tack the sheet in place. Push the router through the drywall at the mark. Move laterally to the edge of the opening. For an electrical box or light fixture, you jump to the outside of the rim and follow the edge counterclockwise. For a plain cut out you follow the inside of the opening with the router. Make sure you push the wires back into the box before routing the drywall.

You can also use the router to cut out opening on a sheet before you put it in place. This takes some practice as the router cuts the board easily and does better when it has something to follow. Some drywall hangers score the drywall and the router will track in the groove.

Most homeowners do not have a drywall router and it is probably not worth purchasing one for a small project. Got a tool fetish, you can own one of these high powered babies for around $75. With a little creativity you can even manage to justify it to your spouse.

How To Cut Cement Board

Learning how to cut cement board is important if you have a bathroom remodeling project. Can you cut cement board with a utility knife? That is a $64,000 question. The answer is yes, but it is not fun. As mentioned above cement board is two fiberglass mats with a cement core.

You and use a utility knife to score the fiberglass. You have to score it several times and the blade will have a tendency to jump out of the groove.

With the fiberglass mat scored the cement board will break similar to drywall. The problem is that it does not break cleanly or pretty for that matter. Sometimes hunks will break free that are not anywhere near the line that you scored.

A much better choice is a diamond circular saw blade. Cut the cement board the same way you would cut plywood. Do it outside or in the garage. Cutting it dry with a diamond blade will generate a lot of dust. Wear a mask.

Summary

For related drywall repair topics see the articles 'How To Fix Drywall', 'Patching Drywall', 'Repairing Large Holes in Drywall' and 'Taping and Mudding Drywall'.

Cutting drywall for you home repair projects should not be a big problem. A few tools and a couple of tricks and you are in business. Not really rocket science and since you are taping over it, it is forgiving. Are you glad that you learned how to cut drywall?

Maybe 'glad' isn't the right word. How about satisfied? Is that a better word? All right let's concede that it would not be your first choice for a fulfilling experience. You do have to admit, however, that it did save you a few bucks.

Using a Dustless Drywall Sander

You will appreciate dustless drywall sanding a lot more after your spouse is done yelling at you for making such a mess. Drywall dust is, without a doubt, one of the messiest substances known to man. The dust is so fine and it travels fast. It is amazing where it can get and how much of it can get there.

Tracking it through the house is another popular mistake. All of the praise you can get from a good drywall job will be negated by the scorn you will receive from making a mess.

For related information, see the articles 'How To Patch Drywall' and 'Taping and Mudding Drywall'.

Drywall dust does not have to win. It does not have to ruin your drywall repair project. Find out the options you have for dealing with drywall dust. It could be as simple as the kind of drywall mud you use.

You have two options when it comes to dustless drywall sanding. One would be to deal with the dust before it gets everywhere. The other would be to not create any dust in the first place. The method you choose will depend on several factors. Doing a better job of finishing the drywall can also help.

Containing Drywall Dust

Do not underestimate how pervasive drywall dust can be. It has the ability to get everywhere. It will put a layer of fine white powder on everything. When you are planning on dry sanding, you need to protect the area.

Containing the mess is a good idea with any repair project. Cover the floors before you start. Drape plastic over the doorways and seal them with blue masking tape. Put walk off mats down wherever you will be going in and out of the area.

Another silent enemy is your heating and cooling system. Cover up the registers and cold air returns. Dust that gets sucked into you heating system can wind up spreading through the whole house. Even when you use dustless drywall sanding techniques it is a good idea to isolate the area.

Drywall projects are among the messiest you will get involved with on your home. The other problem is that it normally takes place inside of your home.

Vacuum Sanding Drywall

Vacuum sanding drywall is another option. You do this by attaching a sanding head to a shop vac. This method has the advantage of achieving the same quality as conventional sanding. The vacuum cleaner captures the dust as it is generated. Sanding heads that can attach to a shop vac can be purchased for around $20. Not a big investment for saving yourself some cleaning.

Unfortunately, there are a few issues to contend with. Vacuum sanding drywall with a shop vac is not totally dust free. Some dust escapes the suction and can still get in the air. Drywall dust is very fine and can clog a filter on a shop vac very quickly, even if the filter is new. When this happens the shop vac will start to blow out as much dust as it picks up. Not a pleasant thought. Purchasing the sanding head is not a major investment. However, it is still an expense.

You need to use sanding screen with this type of sanding head. The holes in the screen allow the air to pass through. You need to purchase the screen and a sanding head before you can start. Make sure you have a clean filter for the shop vac. Sand the drywall the same way you would with a regular sanding head. Sand lightly, in long even strokes until the surface is smooth. Use your hand to make sure the area is smooth.

Check the filter often, cleaning as needed. The mess will be massive if the filter clogs. After you are done you want to clean the filter thoroughly.

Dustless Drywall Compound

A few years ago a new product was introduced to be used in the war on drywall dust. Dustless drywall compound made its debut and dustless drywall sanding took a giant leap forward. The United States Gypsum company started producing a light weight dustless drywall compound.

Light weight drywall compounds have always been a friend to do it yourself homeowners. They are easier to work with and require less sanding than the older standard compounds. Adding dust free technology to an already popular compound was a great innovation.

Dust free does not mean mess free. The way the compound works is that the dust particles stick to each other forming larger particles that fall harmlessly to the ground. This residue is easily swept up and disposed of. The fine white dust that becomes airborne is not a factor.

With this product, dustless drywall sanding has never been easier. Most home supply stores carry this compound. The USG brand is called "Sheetrock Joint Compound - with Dust Control". It is sold in one gallon and three and a half gallon pails.

Summary

Patching and repairing drywall is one of the messier home repair projects you can tackle. The white powder, the gypsum, can get everywhere. When sanded the white powder is very fine and gets in the air. Once it is in the air, it travels through the house, putting a layer of fine white powder on every surface.

The smart thing to do is employ some form of dustless drywall sanding in your project. You can eliminate most or all of the fine white dust. This will make everyone in the house happier. It will also save a lot of cleaning time. You are already tired from the repair project. No need to get exhausted cleaning up afterward.